SSS

Home Solutions

Greetings from Er. Satish B.E (Civil), Chief executive of SSS Home Solutions Lightweight Concrete Division, a leader in innovative and cost-effective roofing solutions.. With over three decades in the building construction industry, I have been a founding partner of M/s AGP Homes, successfully promoting 30+ residential projects in Chennai. My expertise extends to guiding CLC block-making companies in Chennal, leading to innovative solutions for effective CLC (Cellular Lightweight Concrete) applications in rooftops and sunken slab fillings.

Our lightweight concrete technology has gained wide acceptance in the construction industry, due to its cost efficiency, time savings, and superior performance.

Choosing the right weathering course material is crucial for long-term durability, cost savings, and energy efficiency. Here's why CLC is an excellent choice for modern construction projects

1.COST SAVINGS

CLC weathering course costs ₹80 -

100/sq.ft, whereas the conventional brick jelly lime concrete method costs ₹160-200/sq.ft,

including hacking with kaduka and jaggery water. That's nearly 50% savings!

2.FASTER INSTALLATION

CLC weathering course requires only one day to lay,

compared to 30-40 days for conventional brick jelly lime concrete. This significantly

reduces project duration.

3.REDUCED STRUCTURAL LOAD

CLC weighs 900-1100 kg/m³

Traditional brick jelly lime concrete weighs 1800-2000 kg/m³

50% weight reduction leads to lower structural reinforcement costs.

4.LOWER WATER ABSORPTION

Initial absorption is 20%, reducing to 6-8% over time.

CLC prevents water percolation, ensuring quicker rainwater drainage.

Reduces risk of structural deterioration by protecting steel reinforcement from corrosion.

5.STRENGTH IMPROVEMENT OVER TIME

Compressive strength: 2-3 MPa in 28 days, increases to 6-8 MPa with aging due to continuous

hydration of lime and fly ash.

6.HEAT RESISTANCE

CLC transfers minimal heat to the RCC slab below, enhancing energy efficiency by keeping

interiors comfortable year-round-cooler during summer and warmer in winter.

This helps reduce reliance on air conditioning and heating, leading to potential energy

savings.

7.SOUND INSULATION

The air voids in CLC act as sound barriers, minimizing noise transfer. This is especially

beneficial in residential buildings, where foot traffic on terraces is common.

Traditional brick jelly lime concrete takes 40 days for 2500 sq. ft, weighs 1800 kg/m³, and costs ₹160-200/sq.ft.

CLC weathering course takes just one night (10 PM - 6 AM), weighs 900 kg/m³ after curing and costs ₹80-100/sq.ft.

Suitable finishings: Kerala burnt clay tiles, terracotta pressed weathering tiles, or cool roof tiles.

✔ Terrace surface must be cleaned properly.

✔ Coving plastering at parapet wall & slab junction to be completed.

✔ Waterproof coatings & leak tests (e.g., ponding) should be verified.

✔ Plumbing lines running along parapet walls should be completed.

✔ Bull marks to be fixed at 2-3m intervals for proper leveling.

✔ Expansion joints (4½-inch brick walls) required every 15m.

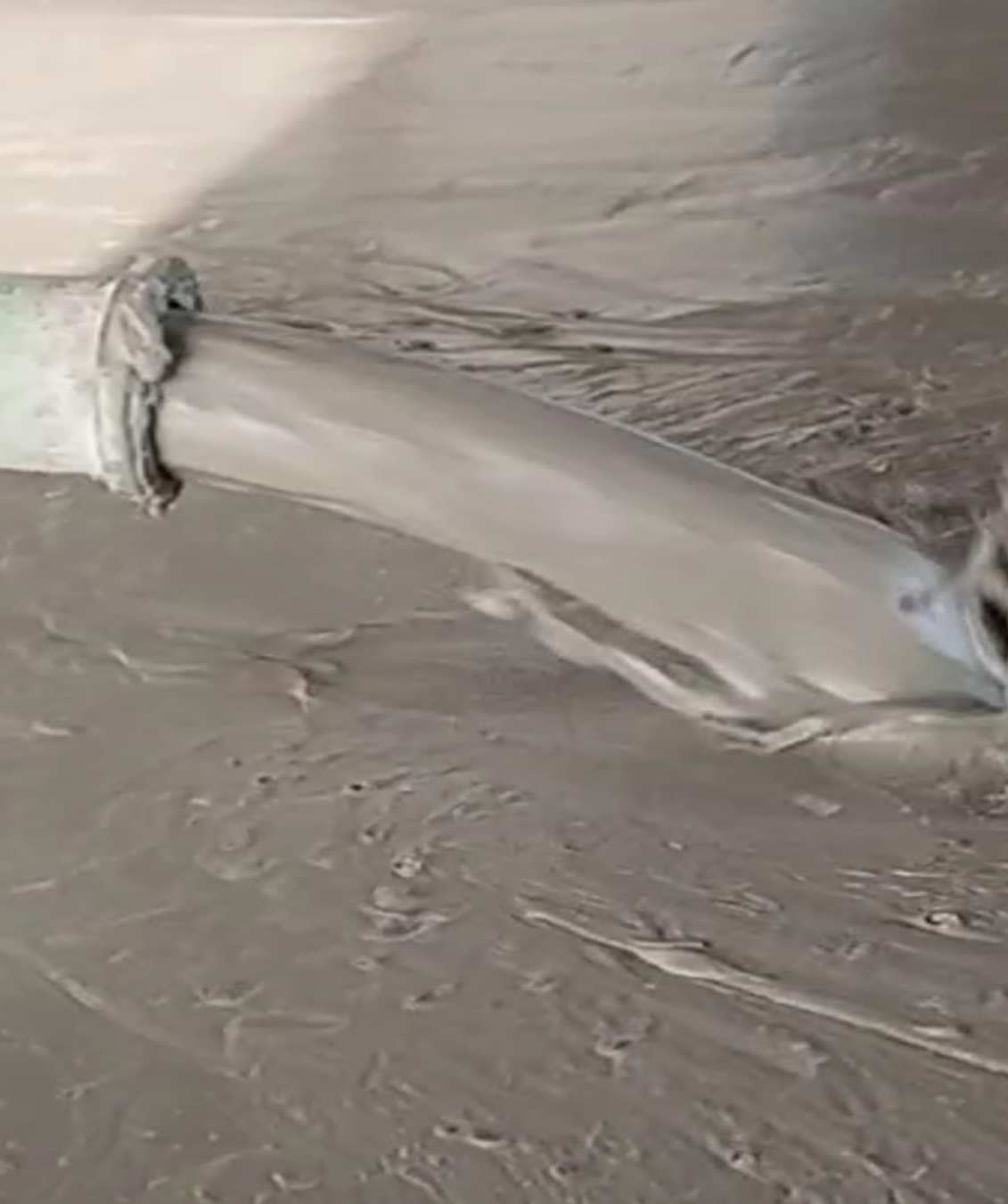

✔ Scaffolding for slurry pipe delivery support to be provided.

Our lightweight concrete is not laid for waterproofing purpose but is designed to protect the top slab from weathering while also enhancing thermal insulation and reducing structural load. To ensure complete waterproofing, additional measures should be taken as per project requirements. They also provide 7 other benefits listed above.

Payment Terms: 80% advance (4 days before concreting), balance within 7 days after invoicing.

WEATHERING COURSE USING CELLULAR LIGHT WEIGHT CONCRETE [CLC] AN ALTERNATE TO CONVENTIONAL BRICK JELLY LIME CONCRETE

MORE EFFECTIVE & TIME SAVING LESS WEIGHT, LESS ABSORPTION OF WATER, LESS HEAT ABSORPTION, LESS HEAT TRANSFER, LESS SOUND TRANSFER, LESS PROJECT DURATION, ECONOMICAL[ MONEY SAVED] CAN BE USED IN SUNKEN SLAB FILLINGS, TO LEVEL THE ENTIRE FLOOR